It’s Caisson Season!

Steel America’s happy to announce that we have been awarded contracts to fabricate two caisson gates. Our amazing team has fabricated five caissons to date and we are excited to fabricate two simultaneously in our fabrication shop. With the award of Caisson # 2 & # 4, that Steel America has built all of the caissons for Norfolk Naval Shipyard and the largest supplier of caissons in the country

Caisson Gate #8 – Portsmouth, VA.

Caisson Gate #3 – Portsmouth, VA.

Caisson Gate #3 – Portsmouth, VA.

Caisson Gate #1 – Boston, MA.

Caisson Gate #1 – Boston, MA.

Caisson Gate #1 – Portsmouth, VA.

Caisson Gate #1 – Portsmouth, VA.

Caisson Gate #3 – Kittery, ME.

Caisson Gate #3 – Kittery, ME.

Steel America has been awarded the fabrication of the caisson gate for Drydock #4 of the Norfolk Naval Shipyard in Portsmouth, Virginia. Designed to control flooding of the drydock for vessel overhauls, the caisson stands at 56′ 6″ tall, occupies a length of about 132′ 6″ of drydock width, and is comprised of nearly 600 tons of steel. The design/build contract is currently underway with the production of fabrication drawings and material procurement. The keel is expected to be laid by early June of 2020. Fabrication will consist of manufacturing five modules within the shop, which will then be transported to the West Yard by way of a heavy lift transporter. After structural assembly of the Caisson, the structure will be fitted with Pumps, valves, electrical and HVAC systems. Once outfitting is completed the Caisson will be launched by way of our 1000 metric ton Marine Travelift. Following testing of all systems, the caisson will be transported by way of tug to Portsmouth, Virginia for final testing and delivery.

Caisson gate for Drydock #2 of the Norfolk Naval Shipyard in Portsmouth, Virginia. Designed to control flooding of the drydock for vessel overhauls, the caisson stands at 49′ 4″ tall, occupies a length of about 101′ 4″ of drydock width, and is comprised of nearly 400 tons of steel.

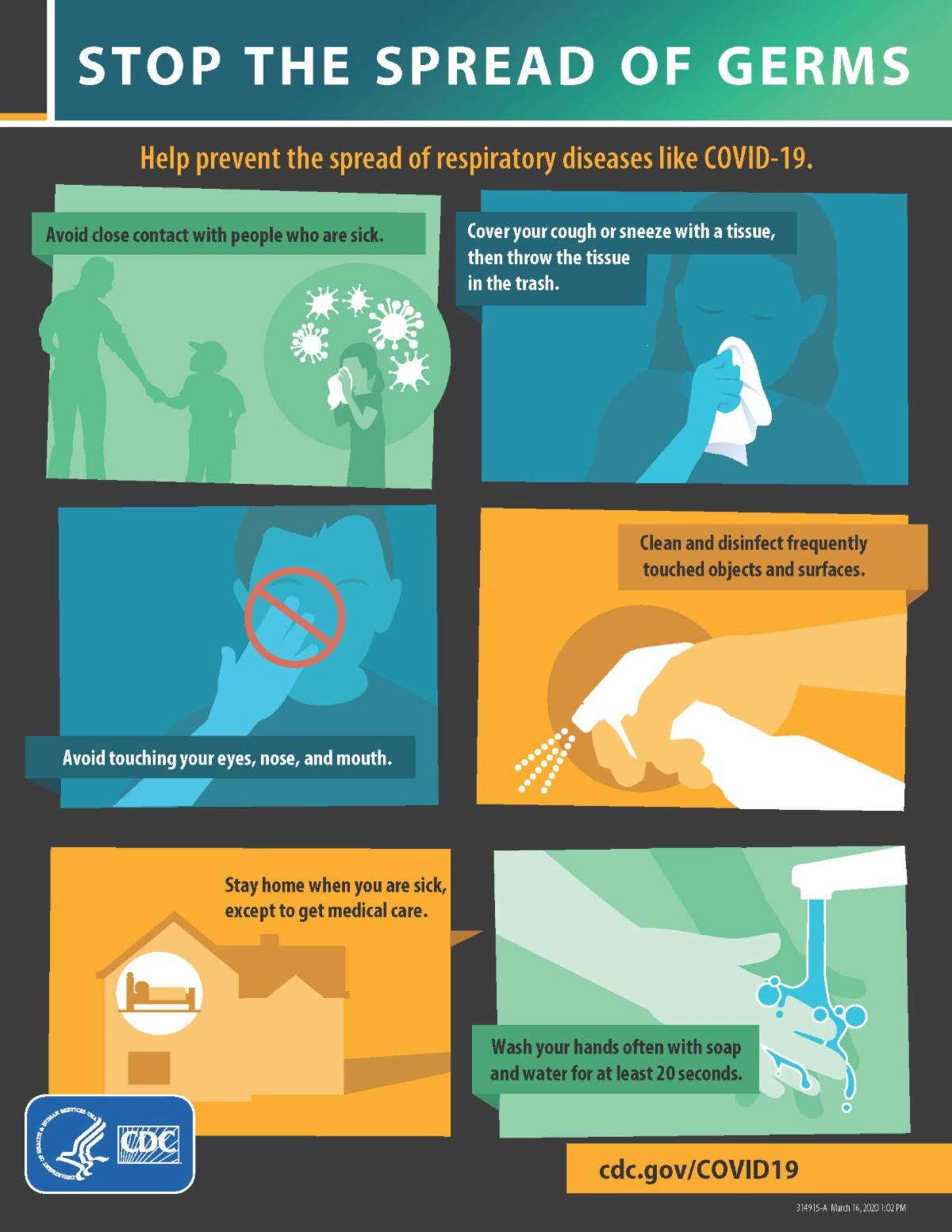

Stop the Spread

In The Fabrication Shop…

Steel America was contracted to construct 5 decks for the VCS (Virginia Class Submarine) that will be joined to form the Habitability module for the fifth block of submarines to be delivered to the US Navy. Steel America is the first sub-contractor to ever build these outside of the prime contractor where it has always been constructed. Three out of the five decks have been delivered with the remaining two to be delivered in April 2020.

In the Machine Shop…..

Steel America is one of the premier NAVSEA Certified Machine Shops for the U. S. Government and is in the process of a long term contract to manufacture new propulsion shafts for various customers and the U.S. Navy. This consists of setting the new shaft forging in a lathe, inspecting the forging, rough turning, reports, maintaining straightness during machining, installing new sleeves, turning, milling, drilling, threading, balancing, building shipping crates, packaging, coatings and fiber glassing as per the TRS requirements under continuous government inspection. Steel America provides quality safe services that consistently meets or exceeds the requirements of our customers.

To schedule a tour of our facility please send an email toawilliams@steelamerica.net or call 757-545-5311 x3650

Join our TEAM!

We are always looking for highly motivated and talented people to join our already amazing team. Apply today!